Smart car lighting is constantly evolving, turning to LED-based solutions to improve road safety, achieve energy savings of 3 to 5 times, and enhance user experience, and innovative car lamp design and reliability improvements continue to broaden the new realm of automotive lighting. . Onsemi pays attention to the trend development in the automotive field, and continuously introduces innovative intelligent power and intelligent sensing technologies to ensure road safety. It is also a pioneer and leader in the field of automotive lighting. This article focuses on system-level applications of automotive exterior lighting and semiconductor solutions related to ON Semiconductor’s designs, including matrix/pixel lamps, styling customization, and vehicle-to-everything (V2X).

Headlamp and SPI Interface LED Driver Module

Headlights include low beam, high beam, daytime running lights, position lights, turn signals and fog lights. Because the total power of the system is very large, and many functions are integrated, more heat dissipation is required, and the design is relatively complex. Therefore, the LED driver circuit of the headlamp is generally made into a module alone, which helps to speed up the research and development cycle and platform. Project management for flexible use with a variety of vehicle structures and lighting group shapes. Advanced LED driver module optimizes headlight performance, can power a single LED bead or multiple LED strings, programmable to control various types of automotive lights, minimize power consumption, includes safety diagnostics and on-board Network (IVN).

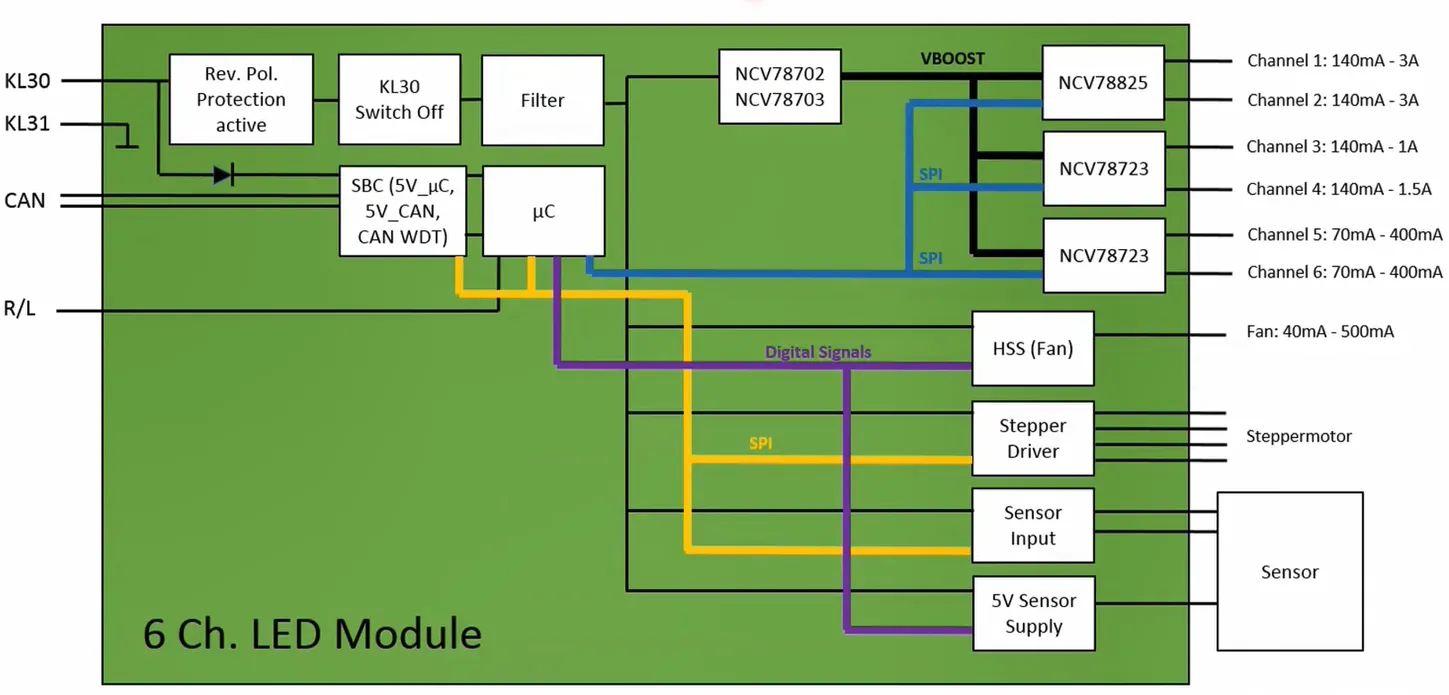

ON Semiconductor’s LED driver modules have higher integration and reliability. The platform design provides scalability and flexibility, and is suitable for various headlamp designs. Intelligent functional partitions help reduce costs and achieve unique front To improve the lighting effect, reduce carbon emissions, and help electric vehicles to increase the battery life. Figure 1 is a block diagram of an LED drive circuit in a headlamp system. The 6-channel LED module can drive multiple groups of LED light strings, corresponding to high beams, low beams, column lights, corner lights, turn signals, etc., including LED driver chip, stepper motor driver chip, various sensor interfaces, power supply and power management chip, interface protection chip, car networking chip SBC and single-chip microcomputer, etc., are a small system that can work independently.

ON Semiconductor’s single-channel LED driver system-on-a-chip (SoC) integrates the safety and control functions required by car lights, simplifies peripheral devices and optimizes circuit design compared with traditional solutions, enabling designers to quickly complete product design. Suitable for designing LED lights with a single function.

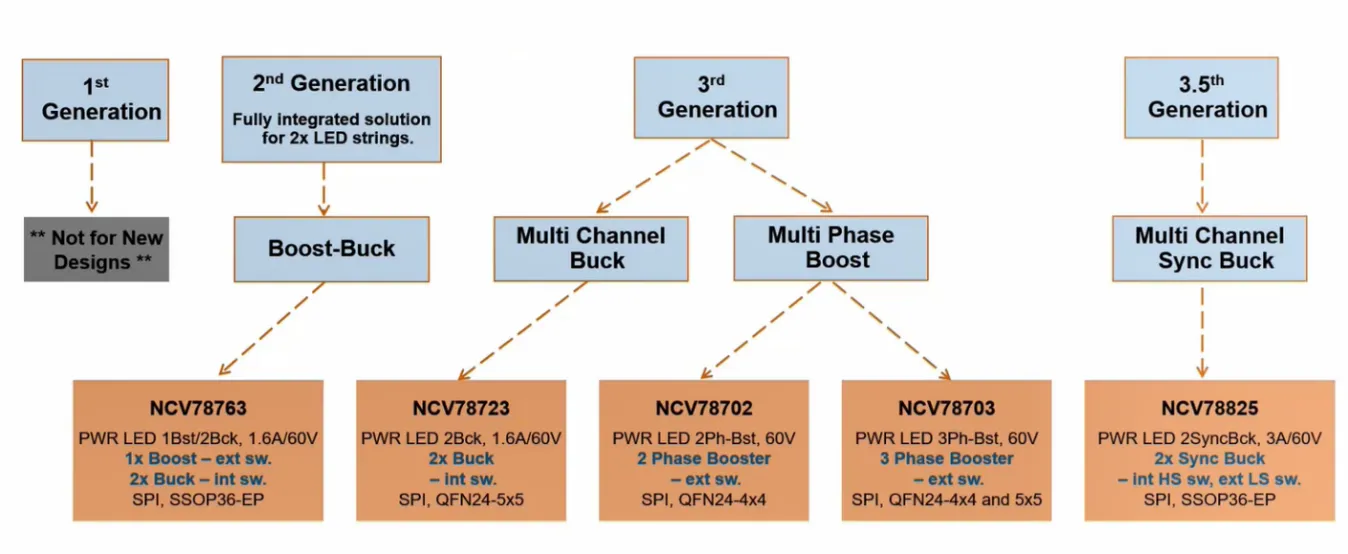

ON Semiconductor has developed 4 generations of SPI-LED driver products. The second generation is the Boost-Buck chip NCV78763, the third generation is the multi-channel Buck chip NCV78723 and the multi-phase Boost chips NCV78702, NCV78703, the maximum output voltage is 60 V, which is the highest voltage output capability among similar products on the market. The 3.5th generation is a multi-channel synchronous rectifier Buck chip NCV78825, with a driving current capacity of up to 3 A, which is also the largest current driving capacity among similar products on the market. Products after the 3rd generation are suitable for more than 3 groups of LED light strings.

If two NCV78763s are used, 4 different LED light strings can be driven, and two Boosts can be connected in parallel to output more power, but this is only a simple power addition. For driving higher power LED light groups, it is recommended A Boost chip that works alternately with multiple phases. In practical applications, one NCV78702/NCV78703 can be combined with multiple NCV78723s to drive 4 to 12 LED light strings of different powers, covering high beam, low beam, column, steering, corner lights, fog lights and other functions.

On this basis, if the NCV78825 with synchronous rectification Buck technology is added, it can drive higher-power LED lamp beads, improve the energy efficiency of the system and reduce heat generation.

Advantages of Boost-Buck Power Architecture

As a stable voltage source, Boost can guarantee the accumulated voltage drop requirement of multiple LED light strings. Buck acts as a stable current source to directly drive LEDs to emit light. Since the current source is not affected by load voltage transients, it can achieve fast switching. It has excellent performance in adaptive high beam (ADB) matrix/pixel light groups. Performance. This architecture is also conducive to platform-based design, which can be combined with 4 to 12 groups of LED light strings. High integration can reduce the number of peripheral components and bill of materials (BOM) costs.

Pixel controller for matrix/pixel headlamps

The matrix/pixel light group is an advanced front lighting system for automobiles, which can enhance the forward lighting vision, not only for the driver, but also for the surrounding traffic environment such as anti-glare, follow-up steering, illuminated obstacles, pedestrian avoidance Wait. A single pixel in the beam can be controlled on/off, where a pixel is a single LED bead in an LED array, and each pixel has an area illuminated by the beam. The intelligent beam illumination can adapt to the driving intention and traffic environment to improve safety. Modular design adapts to any architecture.

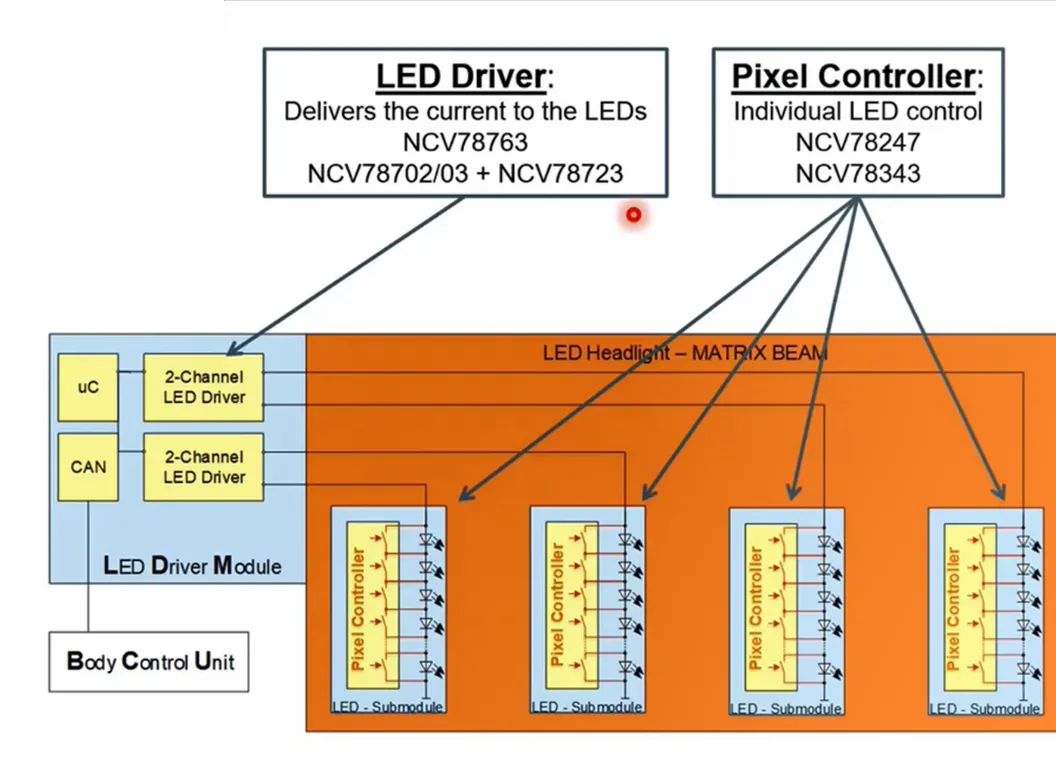

Advanced matrix/pixel light cluster optimizes headlight function in a variety of driving scenarios, including illuminating longer distances, switchable beams when cornering, and more clearly illuminating pedestrians and obstacles in the road, minimizing opposite directions The glare generated by the vehicle can control the switch of a single LED pixel as required, and includes functions such as safety diagnosis and vehicle networking. Figure 4 is an example of an application block diagram of ON Semiconductor’s pixel/matrix light group consisting of 4 LED light strings.

In the pixel light control chip, 12 bypass switches are integrated, and each bypass switch can be controlled independently. We set every 3 bypass switches as a group to form 4 groups of connection structures, so as to flexibly match Different functional modules such as high beam, low beam, steering, day travel, grille, modeling lights, etc. Because the driving current of different LED light panel modules may be different, this can expand the application scenarios of the pixel control chip, not only limited to the matrix/pixel light application composed of far and near lights, but also to realize the parallel connection of multiple groups of switches, making The current that the switch can handle is multiplied to drive higher power LEDs.

LED Light Sets – Series Driver vs. Parallel Driver

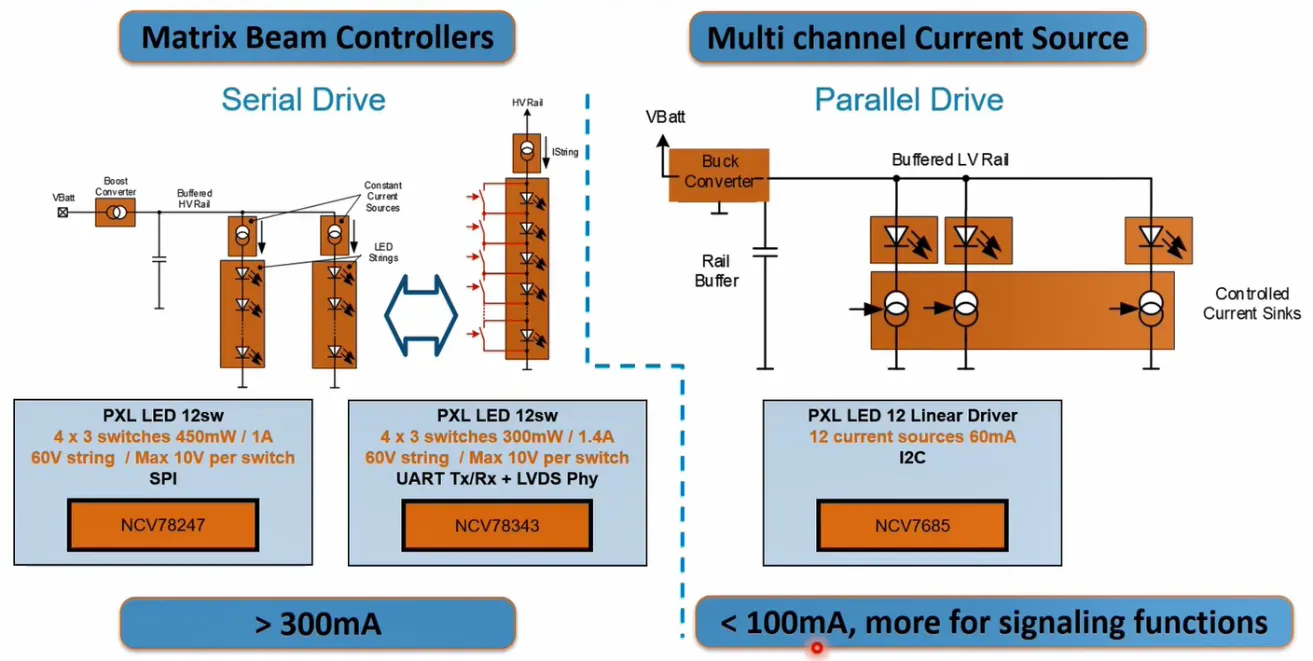

In a wide range of car lights, there are two types of LED light groups: series and parallel. The matrix/pixel LED light group described above is a series structure. When the rated working current of the LED lamp bead is greater than 300 mA, the series structure is generally selected. The disadvantage of this structure is that the voltage drop is large. ON Semiconductor’s LED driver chip has a Boost controller that can boost the voltage up to 60 V, and the Buck chip is responsible for controlling the stable current output of the entire light string. Therefore, ON Semiconductor’s LED driver using the Boost-Buck power structure is this series type. An ideal solution for LED light strings, and ON Semiconductor’s pixel light control chips NCV78247 and NCV78343 also perfectly match this series of LED light groups. The NCV78247 integrates 12 matrix switches, each with an overcurrent capability of 1 A, including an SPI interface. NCV78343 also integrates 12 matrix switches, the overcurrent capability of each switch is increased to 1.4 A, including UART interface, it can be used not only for matrix light groups composed of high and low beams, but also for turn signals with animation effects, daytime running lights, Grille lights, modeling lights and other scenes.

When the rated working current of the LED lamp bead is less than 100 mA, the parallel drive is generally selected. The total rated working current of the LED lamp string with this structure will be the accumulation of all the lamp strings. Due to the parallel structure, the voltage drop of each channel is keep it the same. Therefore, it does not need a Boost boost circuit, matches a Buck converter at the input to stabilize the total input voltage, and then uses a multi-line constant current source to be responsible for the stable driving current of the LED. ON Semiconductor provides the corresponding NCV7685.

LED linear drivers for rear combination lamps (parking lights, tail lights, turn signals, modeling lights)

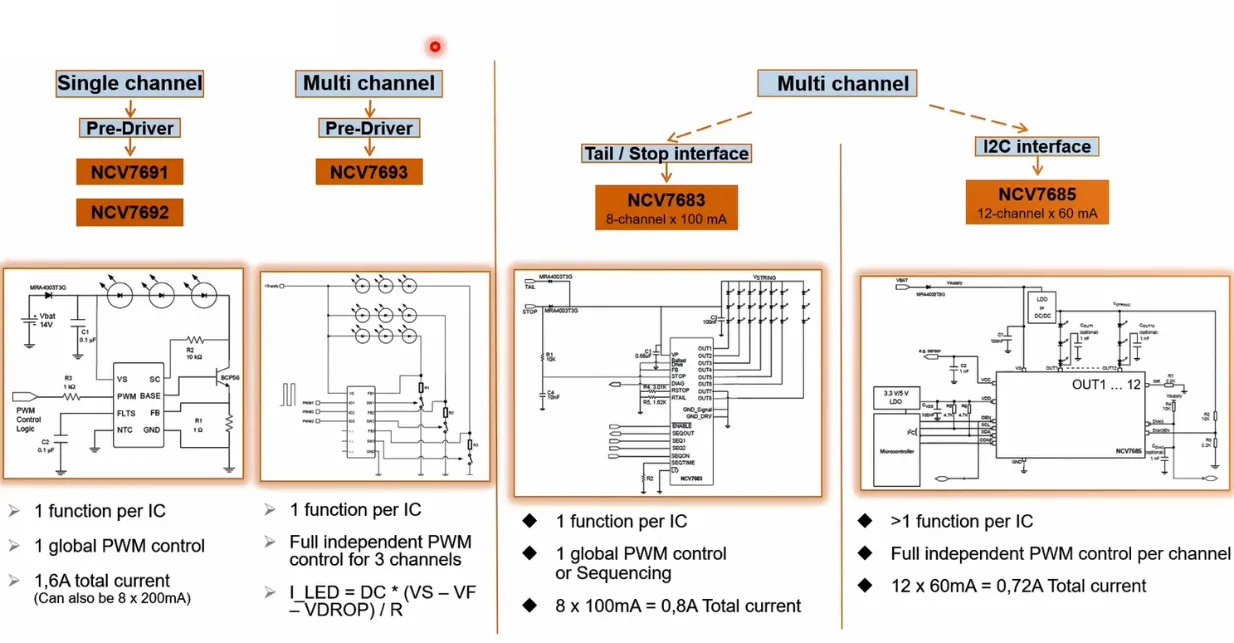

This type of light is a signal light, used to remind surrounding vehicles and pedestrians of the upcoming driving intention of the car, including turning, braking, parking, etc. At the same time, various shapes on the body can also be used as a sign of the car’s identity. The current is generally less than 100 mA. The rear combination lights have these high-level functions: Enhanced parking lights, tail lights, and turn signals are dynamic segmented light signals. String, multi-string LED lamp beads, higher energy efficiency, less loss, and include safety diagnosis function. ON Semiconductor provides single-channel and multi-channel LED linear drivers, as shown in Figure 6, the single-channel pre-driver chip has NCV7691/92, the multi-channel pre-driver chip has NCV7693, the multi-channel direct driver chip has NCV7683 dedicated to braking and parking, And NCV7685 with I2C interface.

NCV7692 and NCV7693 are constant current controllers that drive external NPN transistors through PWM control signals to provide stable linear currents. Because the NCV7693 can control 3 LED light strings, it can be combined into a dynamic switching effect. The NCV7683 and NCV7685 are 8-channel linear current sources with integrated power switches, each with a current drive capability of 100 mA and 60 mA, respectively. NCV7685 has two working modes: in standard mode, the parameters of the chip are set through the peripheral circuit without the intervention of the single-chip microcomputer, but only simple switching operations can be performed; in the I2C mode, the single-chip microcomputer configures the parameters of the chip through the I2C interface. Realize a variety of LED light string animation effects.

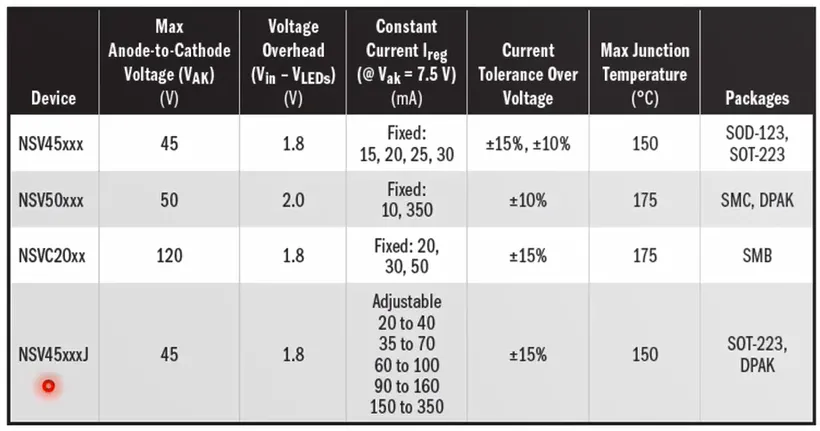

LED constant current regulator

This is a cost-effective solution in simple automotive lighting applications, and designers can match the most suitable device for the application based on the key parameters in the table below. These LED constant current regulators provide constant current over a wide voltage range for constant brightness. Under high temperature conditions, the negative temperature coefficient can protect the LED.

Summarize

Exterior automotive lighting has paved the way for further improvements in user experience and safety. Increasingly diverse options for brand equivalence and styling, as well as improved reliability, are constantly opening up new realms of automotive exterior lighting. ON Semiconductor provides corresponding semiconductor solutions for headlamps, matrix/pixel lamps, and rear combination lamps, with high energy efficiency, high integration, high reliability, and platform design to achieve scalability and flexibility, helping designers to innovate And simplify and speed up development. ON Semiconductor’s smart power supplies are paired with intelligent sensing technology, paving the way for improved road safety.